What Defines the Best Custom Shirt Printings Near Commack?

Opening Thread: Weaving the Fabric of Custom Shirt Excellence in Commack

From idea to ink mapping the custom apparel journey

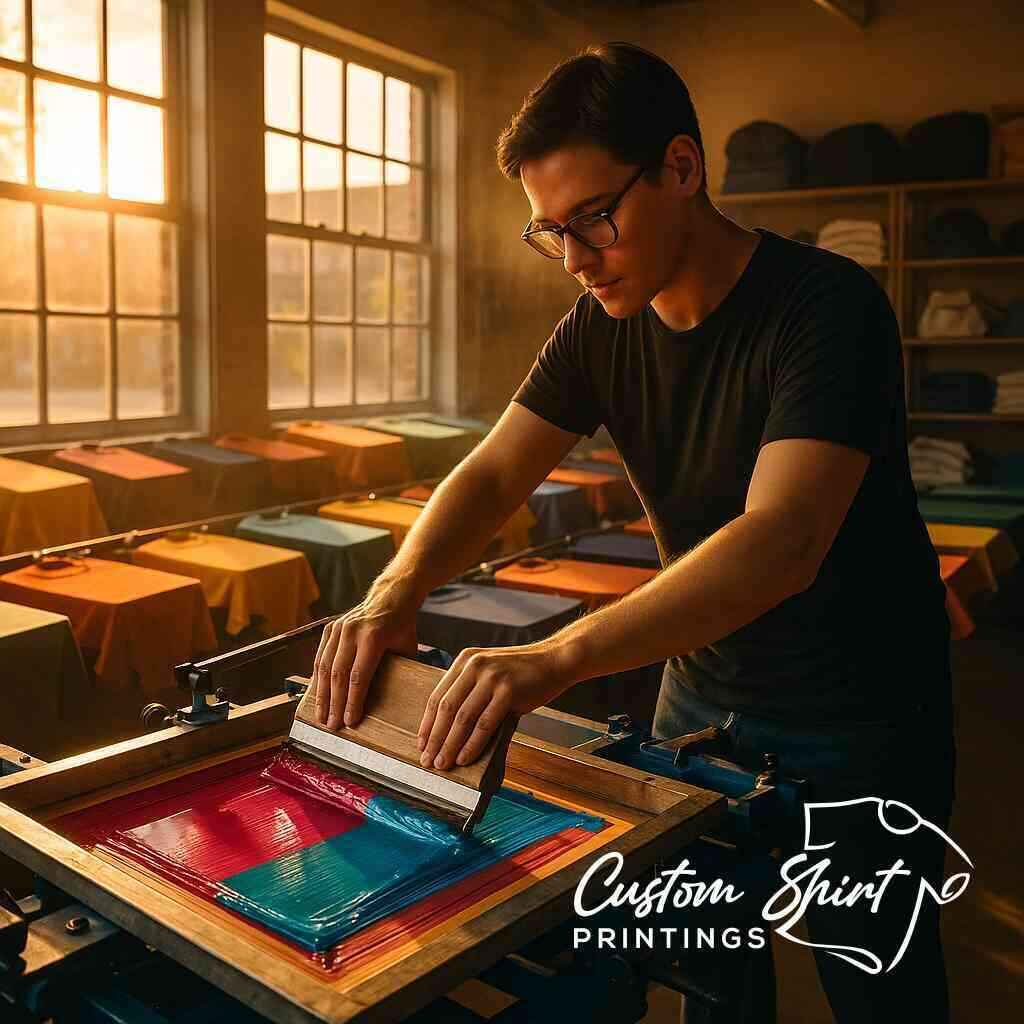

Designing memorable apparel begins the moment inspiration strikes and ends when vibrant ink settles into soft cotton. Shoppers walk into a local t-shirt print shop in Commack NY armed with sketches, Pinterest boards, or phone photos. Seasoned consultants translate those visuals into precise mockups within the custom apparel design studio, using industry-leading software that displays realistic proofs on tees, hoodies, or tote bags. This guided process eliminates guesswork, empowering clients to adjust placement, color, or garment style before a single screen is burned. The result is custom shirt printing that looks exactly like the concept living in your imagination.

Experienced press operators then convert artwork into production files, selecting premium screen printing Commack techniques or high-quality DTG printing Commack workflows based on fabric, order size, and color depth. Soft feel waterbased prints satisfy eco-friendly ink garment printing goals, while small batch shirt printing services keep minimums low for passion projects. Rush order t-shirts Long Island customers love move to the front of the queue through carefully managed scheduling that never sacrifices quality. Throughout each stage, barcode tracking and visual inspections maintain accountability, ensuring every piece meets tight tolerances. When the boxes finally open, brands, bridal parties, and local team uniform creators see their story celebrated in cotton and thread.

Why a Long Island custom t-shirt shop beats one-size-fits-all online services

Community matters when deadlines loom or colors must match a corporate PMS swatch. Choosing a shop that offers pantone-matched screen printing on Long Island means regional businesses receive exact brand hues without shipping delays or generic approximations. Face-to-face collaboration allows immediate feedback on art scale, thread density for personalized hoodie embroidery, and fabric weight comparisons across the most requested shirt brands. Clients leave with tangible confidence rather than abstract promises.

A Long Island custom t-shirt shop also understands island geography, traffic patterns, and seasonal event cycles that national giants often overlook. That local insight drives smarter production calendars so event merchandise printing near me arrives before street fairs, charity walks, or playoff games. Walk-in sample racks let buyers feel ring-spun cotton, tri-blends, or performance poly before committing, avoiding disappointing surprises. Finally, reliable pickup options and same-day courier partnerships deliver finished apparel without the carbon cost associated with cross-country freight.

Decoding custom shirt printing terminology from DTG to tackle twill

Newcomers hear acronyms like DTG, DTF, and PVC and quickly feel overwhelmed. Understanding that high-resolution DTG prints near Suffolk County use precision inkjets to spray water-based pigments directly onto garments demystifies the process. DTG excels at photo-realistic gradients, making it ideal for full-color album art, fundraising shirt campaigns, or vintage style shirt reprints. Screen printing shines when quantities rise or limited spot colors dominate, reducing cost per piece while retaining vibrant opacity.

Decorative stitching fundamentals such as tackle twill, chenille, and satin stitch elevate lettering with dimensional flair absent in flat prints. Personalized hoodie embroidery utilizes durable rayon or polyester threads, resulting in logos that withstand numerous spin cycles. Meanwhile, corporate logo apparel branding often combines screen-printed fronts with stitched sleeve hits, marrying affordability and texture. Knowing these options lets organizations unlock the full potential of branded apparel without overspending. Technical clarity becomes the first step toward turning creative ambition into production reality.

Pillars of Premium Production Inside a Commack Custom Apparel Design Studio

Color-match Pantone screen printing and soft feel waterbased prints

Premium screen printing Commack experts treat color accuracy like science. Technicians calibrate presses to hit exact Pantone values every single run. That dedication ensures corporate logo apparel branding never drifts from official guidelines. The custom apparel design studio further refines hues with soft feel waterbased prints, delivering breathable finishes that please eco-conscious clients. Local restaurants, charities, and youth sports jersey customization projects all appreciate this balance between vibrancy and comfort.

Beyond hue precision, substrate knowledge drives reliable results. Ring-spun cotton, tri-blend, and performance poly each absorb pigments differently. Skilled press operators compensate by adjusting squeegee angles, mesh counts, and flash times. This adaptive approach keeps custom shirt printing efficient even when artwork shifts from wholesale custom tees Commack orders to promotional tote bag imprinting. Ultimately, customers receive consistent saturation across diverse products without incurring extra setup fees.

High-fidelity DTG and eco-friendly ink garment printing breakthroughs

When photographic gradients or vintage style shirt reprints demand microscopic detail, high-quality DTG printing Commack machines take center stage. These direct-to-garment devices spray millions of droplets per second, recreating subtle shadows impossible with traditional screens. Artists pair that resolution with designer mockup tools for shirts, allowing clients to preview every contour before ink touches fabric. The result is museum-worthy clarity that strengthens branded storytelling.

Sustainability remains a parallel priority inside the Long Island custom t-shirt shop. Operators load water-based, eco-friendly ink garment printing systems that release near-zero volatile organic compounds. The studio recycles pretreatment runoff and captures waste fibers, proving environmental stewardship can coexist with commercial excellence. Customers seeking no minimum order custom shirts appreciate knowing their passion projects leave a reduced footprint. Such responsible innovation solidifies the studio’s reputation as a leading apparel specialist in the Commack community.

Personalized hoodie embroidery and small batch shirt printing agility

Dimensional texture elevates decorated garments from good to unforgettable. Using laser-cut twill, merrowed edges, and satin fill, artisans deliver stitch-perfect hoodie embroidery in Commack. Each thread is selected for sheen, tensile strength, and wash resistance, ensuring logos survive countless laundromat spins. Schools, craft breweries, and fundraising shirt campaign printing organizers depend on this tactile method to stand apart during crowded events.

Agility matters as much as artistry. The custom Apparel company maintains dedicated presses for small batch shirt printing services, eliminating large order bottlenecks. A brewer needing fifty corporate hoodies receives equal priority as a festival requesting five hundred custom sweatshirts local shop visitors crave. Flexible scheduling also benefits bridal party shirt customization projects that often finalize guest lists late. That nimble culture underlines why Commack trusts Custom Shirt Printings for both economy and elegance.

Rush order t-shirts and reliable turnaround strategies that matter

Deadlines rarely wait for suppliers. Rush order t-shirts Long Island clients request receive immediate art assistance for t-shirt graphics, bypassing standard queues while maintaining strict quality checkpoints. Barcode systems track every garment, and digital dashboards provide customers with real-time updates, offering transparent peace of mind. Experienced staffers preload screens overnight, shaving critical hours off production cycles without sacrificing stitch integrity.

Distribution logistics complete the promise of reliable turnaround custom tees. Couriers mapped to the island geography of Long Island follow optimized routes, ensuring completed boxes reach storefronts or event merchandise printing near me sites ahead of schedule. The studio offers fast turnaround tee delivery on Long Island only when craftsmanship meets transit strategy. By coupling precise production with smart shipping, Custom Shirt Printings transforms tight timelines into triumphant launches for local team uniform creators and regional businesses alike.

Beyond the Press Experience: Crafting Community and Brand Identity with Custom Shirt Printings

Corporate logo apparel branding and wholesale custom tees game plans

Custom Shirt Printings treats corporate logo apparel branding as an extension of a company’s voice, not just decoration. Brand managers sit with seasoned consultants who translate color guides into Pantone-matched inks that remain consistent from polos to tote bags. For bulk needs, wholesale custom tees Commack clients order arrive in retail-ready bundles, sorted by size and SKU to streamline distribution. Popular blanks like Bella+Canvas triblends, Gildan Heavy Cotton, and Next Level soft-style tees let decision-makers balance budget and hand feel. Combined with premium screen printing Commack techniques, these garments become mobile billboards that withstand weekly washes without color drift.

Sustainability also factors into every game plan. Eco-friendly ink garment printing reduces environmental impact while preserving vibrancy, satisfying modern corporate social responsibility goals. Finance teams appreciate transparent tiered pricing that clarifies how order volume, imprint locations, and rush options influence cost. Marketing departments, meanwhile, value the in-house custom apparel design studio that produces photorealistic mockups so stakeholders approve layouts quickly. The result is a frictionless path from initial mood board to boxed inventory ready for nationwide rollouts or local trade shows.

Local team uniform creators and youth sports jersey customization

From Little League to adult recreation leagues, local team uniform creators crave consistency across jerseys, warm-ups, and fan gear. Coaches collaborate with staff who understand youth sports jersey customization rules for name size, number placement, and league color restrictions. Polyester performance jerseys accept high-stretch plastisol that flexes during play, while cotton coach tees receive soft feel waterbased prints to improve breathability. The shop’s inventory of athletic brands, including Augusta Sportswear and Sport-Tek, allows parents to compare weight, moisture management, and price on the spot.

Customization does not stop at logos. The facility offers optional team roster name & number personalization that arrives already heat-sealed, eliminating volunteer-night press sessions. Barcode tracking ensures every athlete receives the correct size, spelling, and digit before opening day. Order minimums remain low, empowering booster clubs to run mid-season reorders without penalties. Fast pickup options secure uniforms in time for the first whistle, keeping coaches focused on strategy, not logistics.

Bridal party shirts fundraising campaigns and event merchandise printing near me

Brides and party planners turn to custom tees and satin-trimmed tanks that align with wedding palettes without breaking budgets. Metallic rose-gold ink on Bella+Canvas flowy racerbacks adds sparkle for bachelorette weekends, while heavyweight Comfort Colors garments create vintage style shirt reprints for nostalgic gatherings. Designers provide sizing charts that account for varied body types, ensuring every attendant feels comfortable in group photos. Small batch shirt printing services keep minimums friendly for intimate bridal crews.

Community fundraisers and school carnivals benefit from streamlined event merchandise printing near me. Volunteers upload artwork, select tri-blend or ring-spun options, and approve proofs within hours. Tiered fundraising portals enable supporters to place orders directly, eliminating the need for organizers to manage complex inventory. Completed boxes arrive sorted by purchaser, letting committees focus on mission impact. Low-risk, high-reward apparel campaigns become repeat revenue streams that strengthen local causes year after year.

On-site live printing events and the power of experiential marketing

Nothing matches the energy of watching your design appear on cotton seconds after squeegee contact. On-site live printing events transform festivals, store openings, and campus orientation days into interactive brand showcases. Attendees choose garment colors, ink hues, and placement, then witness press operators create their custom shirt printing before their eyes. This tactile engagement solidifies memories, driving social media shares and organic reach.

Custom Shirt Printings dispatches portable presses, flash dryers, and experienced staff who manage crowd flow without sacrificing quality. Brands supply preapproved graphics, while artists tweak variables to keep lines moving. Because the equipment mirrors shop-floor standards, prints remain vibrant and wash-durable. Data capture tools integrate sign-ups and QR codes, funneling newfound fans into email lists and loyalty programs. Experiential marketing turns a simple tee into a powerful, measurable storytelling vehicle.

Art assistance and designer mockup tools fueling inspired custom tees

Brilliant apparel starts with balanced, production-ready artwork, yet many concepts arrive as pixelated screenshots or compressed social icons. In-house specialists offer professional artwork cleanup for apparel that redraws vectors, adjusts stroke weight, and removes artifacts so lines print razor-sharp. This service eliminates the costly surprises of misregistered screens or fuzzy DTG edges, protecting both budget and reputation. Clients review digital proofs on photorealistic templates, ensuring alignment, scale, and bleed meet expectations.

Designer mockup tools for shirts combine thousands of garment silhouettes with drag-and-drop ease, inviting creative experimentation without extra fees. Users swap between hoodies, cropped tees, and heavyweight sweatshirts while comparing colorways side by side. Integrated direct-to-garment technology explained within the platform guides newcomers on how gradients and transparencies behave on fabric. Once finalized, files flow directly into production queues, preserving fidelity from laptop screen to inked fibers. These resources empower artists, nonprofits, and entrepreneurs to unlock limitless potential, confident each imagination will materialize exactly as envisioned.

Closing Stitch: Choosing the Best Long Island Custom Shirt Printing Partner

Quality checkpoints, service metrics, and the ultimate customer checklist

Custom shirt printing success hinges on measurable standards that never leave room for guesswork. Reputable Long Island custom t-shirt shop teams share press logs, thread counts, and wash-test data before production begins. They provide calibrated Pantone swatches under daylight lamps, ensuring your logo shirt design looks identical indoors or outside. Exacting mockup approvals force every detail-placement, scale, and bleed-to pass a five-point review. For a deeper dive into criteria that matter, explore these practical tips for choosing a shirt printer in NY.

Reliable shops verify incoming blanks as carefully as outgoing prints. Staff inspect each Bella+Canvas, Gildan Heavy Cotton, or Comfort Colors garment for stitching flaws, thread pulls, or dye inconsistencies. Barcode tracking links every shirt to its order, documenting size, brand, and color for rapid audits. Final quality checkpoints include light-table inspections that expose pinholes invisible to casual eyes. Only when garments pass every metric do they move to packaging stations.

Balancing budget sustainability and premium screen printing Commack options

Budget planning begins with clear goals, from short-run vintage style shirt reprints to wholesale custom tees Commack corporations need quarterly. Small batch shirt printing services minimize setup costs for fifty pieces, while premium screen printing Commack presses reduce per-unit pricing as quantities climb. Clients compare tri-blend softness against ring-spun cotton durability to stretch dollars without surrendering comfort. Soft feel waterbased prints, though slightly pricier, align with eco-friendly ink garment printing initiatives and appeal to conscious consumers.

Savvy buyers weigh embroidery against DTG or plastisol based on artwork complexity and wear expectations. Personalized hoodie embroidery commands higher upfront investment, yet delivers decades of brand exposure through resilient rayon threads. Meanwhile, high-quality DTG printing Commack workflows thrive on photorealistic art that would require many costly screens. Transparent line-item estimates empower organizations to balance sustainability, tactile appeal, and long-term value, turning spreadsheets into strategic roadmaps.

Building long-term relationships with Commack community apparel specialists

Enduring partnerships transform occasional orders into collaborative growth. Commack community apparel specialists remember favored shirt brands, PMS formulas, and seasonal reorder windows, saving clients hours of re-education each project. They share trend reports on cropped fleece, mineral-wash tees, and heavyweight streetwear silhouettes, keeping catalogs fresh without constant research. Open studio tours let marketing teams witness presses, embroidery heads, and DTG machines in action, reinforcing trust through transparent craftsmanship.

Loyalty also unlocks added advantages such as rush order t-shirts Long Island priority lanes or complimentary art assistance for complex campaigns. Teams planning fundraising shirt campaign printing can reserve press time months in advance, guaranteeing delivery before kickoff rallies. Custom Shirt Printings even coordinates with local couriers for fast turnaround tee delivery on Long Island, reinforcing reliability from print floor to doorstep. Mutual respect, consistent communication, and community pride weave a lasting fabric stronger than any single order.

Frequently Asked Questions

Frequently Asked Questions

Question: How does Custom Shirt Printings ensure that color-match Pantone screen printing and soft feel water-based prints look perfect every time?

Answer: Our premium screen printing technicians in Commack calibrate every press with spectrophotometers and controlled lighting, ensuring that the ink deposits match your exact Pantone values on the first pull. Before production, we generate a physical strike-off on the actual garment you selected: ring-spun cotton, tri-blend, or performance poly to confirm hue accuracy and hand feel. If you opt for soft feel water-based prints, we fine-tune mesh counts and flash temperatures to keep the finish breathable while locking pigments deep into the fibers. Each shirt passes a five-point inspection that checks color density, registration, and wash durability, guaranteeing the consistent, retail-ready vibrancy customers expect from a Long Island custom t-shirt shop they can trust.

Question: I need rush order t-shirts on Long Island for an upcoming event. Can your Long Island custom t-shirt shop really deliver fast without sacrificing quality?

Answer: Absolutely. Rush order t-shirts Long Island projects move into a dedicated fast-track lane the moment art approval is received. We pre-burn screens overnight, stage blanks in size order, and utilize barcode tracking to ensure nothing gets misplaced. Because all printing, screen printing, DTG, and personalized hoodie embroidery are done in-house at our Commack facility, there are no third-party delays. Local couriers pick up finished boxes the same day they clear quality control, ensuring reliable turnaround, custom tees reach your venue on time. Even under tight deadlines, every garment still undergoes our full inspection protocol, so you never have to trade speed for craftsmanship.

Question: In the blog piece What Defines the Best Custom Shirt Printings Near Commack? you mention both DTG and screen printing; how do I decide which custom shirt printing method is best for my artwork?

Answer: Start by looking at color count, detail level, and order size. High-quality DTG printing machines excel at photo-real gradients, unlimited colors, and small runs, perfect for vintage-style shirt reprints, fundraising shirt campaign printing, or multicolored event merchandise printing near me. Premium screen printing Commack presses become more cost-effective as quantities climb or when you have one to six spot colors, such as corporate logo apparel branding or local team uniform creators needing hundreds of jerseys. Our custom apparel design studio provides side-by-side digital proofs and per-unit pricing for both methods so you can make an informed decision based on budget, artistry, and timeline.

Question: Our company wants sustainable corporate logo apparel branding in bulk-what eco-friendly ink garment printing options and wholesale custom tees Commack services do you offer?

Answer: We pair water-based, phthalate-free inks with energy-efficient dryers to minimize environmental impact while maintaining bold opacity. You can choose from organic cotton, recycled poly-blends, or Bella+Canvas Airlume tees to enhance your sustainability story. For wholesale custom tees in Commack orders, we offer tiered pricing, SKU-sorted packaging, and blind shipping, providing direct-to-client fulfillment if needed. Because color-match Pantone screen printing is handled in-house, your brand guidelines remain consistent from the first piece to the thousandth, all while supporting a greener production cycle.

Question: Do you offer small-batch shirt printing services for bridal party shirt customization and youth sports jersey customization, and is there a minimum order requirement for custom shirts?

Answer: Yes! Our small batch shirt printing services allow you to order as few as one piece, making bridal party shirt customization, personalized tote bags, or a single sample for youth sports jersey customization completely hassle-free. For teams, we can add individual names and numbers using high-stretch vinyl or tackle-twill embroidery, delivered roster-sorted to save coaches time. Bridal groups love the flexibility of metallic foil, flock, or rose-gold ink on flowy racerbacks without worrying about large-order commitments. Whether you need one keepsake tee or fifty custom sweatshirts for local shop pickup, our no-minimum-order custom shirts policy ensures every idea, big or small, finds its perfect fit.

Frequently Asked Questions

Frequently Asked Questions