What Are Best Bulk Strategies at Custom Shirt Printings

Opening Thread: The Mindset Behind Large-Scale Custom Shirt Printing

Long Island custom shirt printing advantage at our Commack hub

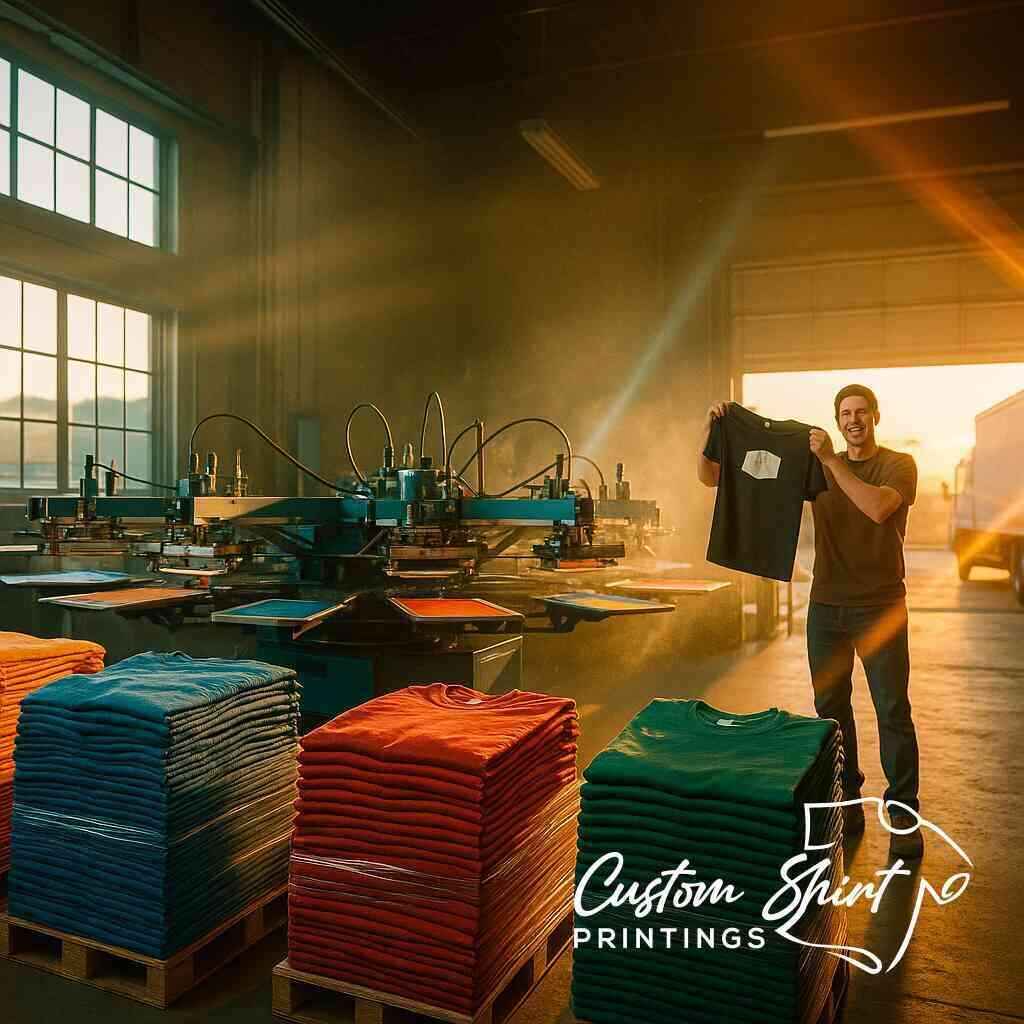

Custom Shirt Printings anchors its production floor in Commack, placing Long Island custom shirt printing minutes from major parkways and freight lanes. That geographic edge speeds raw-garment intake from Bella+Canvas, Gildan, and Champion distributors while keeping delivery windows tight for local clients. Every press operator, designer, and embroidery specialist collaborates inside the same facility, creating an agile feedback loop that chops days off typical lead times. Because decision-makers stand a few feet from the presses, adjustments happen instantly instead of through slow email chains. When you need rapid, high-volume output, that proximity delivers more value than any far-flung factory can.

Visitors who step into our showroom immediately see sample walls stacked with Comfort Colors pigment tees, Next Level tri-blends, Russell Athletic hoodies, and Richardson hats. By touching real fabric and ink before approving art, buyers gain confidence in stitch density, color vibrancy, and fit. The ability to inspect dozens of blank styles side by side makes choosing the right canvas painless. Furthermore, our custom shirt printing in Commack NY headquarters features climate-controlled storage that protects cotton and polyester inventory from humidity swings. As a result, prints cure consistently across every shift, ensuring bulk orders remain uniform from first tee to last.

From custom shirt printing near you to nationwide drop shipping possibilities

Once artwork leaves the design department, our in-house logistics crew engineers routes that stretch far beyond the Island. Many clients start by searching “custom shirt printing near me,” yet quickly realize we can forward stock to branch offices in multiple states without extra hassle. We leverage regional hubs, negotiated carrier rates, and scan-based labels to track every carton. These efficiencies reduce mis-ships, shorten transit times, and protect margins for wholesalers reselling our gear. Ultimately, localized support dovetails with coast-to-coast reach, giving brands the best of both worlds.

For festivals, corporate roadshows, and multi-campus schools, precise arrival timing matters as much as print quality. Therefore, our production calendar syncs with t-shirt delivery logistics software that forecasts carrier delays and reroutes packages proactively. The system even flags surge periods so we can reserve trailer space early, preventing bottlenecks. Coupled with real-time inventory dashboards, organizers know exactly when bulk hoodies, moisture-wick polos, or eco-jersey totes will hit each venue. This transparency keeps sponsorship rollouts and merch tables fully stocked, safeguarding event revenue.

Mapping bulk ambitions from corporate logo shirt bundles to event merchandise drops

A Fortune-500 procurement director may need 10,000 logo shirt design pieces, while a craft-brew festival wants 4,000 commemorative crews. Our account managers blueprint timelines, decoration methods, and budget tiers that satisfy both extremes. Early conversations explore imprint durability, garment softness, and audience demographics, translating into well-targeted blank selections. By aligning creative intent with fabric technology, we prevent overpaying for features your audience will never notice. That strategic groundwork allows ambitious concepts to flourish instead of falter under financial strain.

Name-and-number rosters complicate scaling, yet our automated heat presses handle hundreds of variable backs per hour. Through team name personalization at scale, youth leagues, dance studios, and esports squads receive individualized jerseys without missing shipment milestones. Data merges pull correct spellings and sizes straight from spreadsheets, eliminating manual typo risks. Because the system prints and positions transfers in one pass, labor hours stay predictably low even when rosters change last minute. Consequently, clients enjoy custom tees that feel boutique despite being produced by the thousands.

Understanding economies of scale for apparel runs without compromising quality

Volume discounts in apparel thrive on smart consolidation, not corner-cutting. When artwork shares ink colors across mens, womens, and youth silhouettes, we gang screens to reduce prep fees. That tactic lowers cost per imprint while maintaining the thick, opaque deposit expected from retail brands. Likewise, ordering mixed case packs helps factories pass along bulk textile pricing, further shrinking your unit spend. Yet our press crews still perform tight registration checks every 72 impressions, keeping design integrity front and center.

Choosing the optimal print technology reinforces those savings. We weigh substrate, color count, and turnaround needs before recommending a bulk screen printing service, high-volume DTG, or hybrid workflow. Comparative cost charts reveal break-even points between forty-gallon ink drums and industrial pretreatment sprayers. Clients see where quantity tips the scale toward one method, empowering informed sign-offs. Continuous wash-test sampling then verifies hand feel and longevity, proving affordability never sacrifices durability.

Strategic Blueprint Volume Pricing and Production Engineering

Volume t-shirt pricing tactics and tiered negotiation insights

Custom Shirt Printings treats every bulk inquiry like a math puzzle, mapping stitch counts and ink hits against run size. Our Long Island custom shirt printing pros start with volume t-shirt pricing tactics that bundle setup fees into the first cost break. When quantities climb, we unlock deeper tiered pricing negotiations, shaving pennies that compound into thousands saved. Because our purchasing team buys Bella+Canvas, Comfort Colors, and Gildan by the pallet, those textile discounts flow directly into your quote. The result is transparent, line-item savings that never hide surprises in fine print.

We also analyze art complexity before committing to any press schedule. Limiting specialty foils or puff additives on secondary runs keeps economies of scale for apparel runs intact. Designers may suggest an under-base tweak or halftone gradient swap that trims an entire screen from the stack. These micro adjustments lower consumable usage without visible quality trade-offs. Clients therefore receive retail-ready graphics at warehouse pricing while still hitting aggressive launch dates.

Group order discount planning for schools teams and nonprofits

Schools, churches, and volunteer groups rely on predictable budgets, so our account managers lay out group order discount planning during the first call. We bundle custom tees, hoodies, and tote bags into a single PO, letting every division share the same bulk rate. Layered rebates reward early commitment, encouraging boosters to finalize rosters before practice starts. For nonprofits chasing grant deadlines, we even defer payment until the shirts ship, preserving cash flow.

Organizations running annual campaigns benefit from our partner wholesale apparel program that locks next-season pricing today. By forecasting enrollment numbers, we reserve blank inventory months ahead, protecting you from late-summer shortages. The same contract includes optional refresh orders at the original tier, so new members match the first batch perfectly. Coaches and treasurers appreciate knowing per-shirt costs will not spike halfway through the semester, no matter how chaotic sign-ups become.

Color consolidation for bulk prints cutting costs without dulling designs

Ink selection influences budget as much as garment choice, making color consolidation an essential bulk screen printing strategy. Our creative staff audits every logo palette and identifies near-identical swatches that can share a single screen. Five similar blues often collapse into two strategic tones, slashing setup hours while maintaining vivid branding. We then test those revisions under varied lighting to verify that sponsors and licensing teams approve the shift.

Customers exploring hybrid DTG and screen print approaches often worry bright gradients may flatten during consolidation. We counter that fear with a side-by-side lab test and a detailed screen vs DTF comparison for volume report. The document highlights coverage, hand feel, and wash resilience, showing where each technology excels at large scale. Once you see identical vibrancy on both sample tees, committing to fewer ink heads becomes an easy choice.

Sizing distribution forecasting turning guesses into data-driven inventories

Ordering 3XLs blindly risks costly leftovers, so we replace gut instinct with sizing distribution forecasting rooted in historical patterns. Our database tracks thousands of corporate logo shirt bundles, revealing industry-specific curves for conferences, construction crews, or dance academies. We overlay that intelligence with your demographic data to predict an optimal size mix before a single press warms up. That shift from guesses to evidence can slash overstock by double digits.

We apply the same model to custom hoodies and custom sweatshirts because outerwear skews differently than tees. By adjusting algorithms for garment type and season, we hit bullseye accuracy more often than national averages. Fewer surplus cartons mean lower freight, reduced storage fees, and a greener carbon footprint. Most importantly, every attendee receives a perfectly fitting piece, strengthening brand goodwill with each comfortable wear.

T-shirt mockup approval workflow that protects deadlines

A flawless mockup is the guardian of every timeline, so we engineered a t-shirt mockup approval workflow that merges art proofing with production milestones. Digital renderings arrive within hours, showcasing placement, Pantone references, and stitch paths on photorealistic templates. Clients comment directly inside the cloud portal, preventing email chains from burying urgent tweaks. Once greenlit, art boards feed straight into pre-press, erasing redundant file transfers.

Teams new to bulk orders appreciate our step-by-step mockup approval guide that demystifies terminology like bleed, safe zone, and DPI. Following its checklist keeps revisions minimal, which safeguards your ship date from creeping delays. Production managers monitor each checkpoint through live dashboards, confirming every piece of the puzzle stays on schedule. That transparency builds confidence even when orders top ten thousand units.

Tech-Powered Hybrid Print Solutions for Massive Orders

Choosing between screen print, DTG, and DTF or blending all three

Custom Shirt Printings keeps a balanced toolkit because every massive order carries different technical demands. Screen press lines dominate when single-design runs top several thousand and brand colors must stay identical across cotton, tri-blend, and poly. However, when art files swirl with photo gradients or rapid roster changes, our operators prove the value of high volume DTG printing solutions that spray color without set-up delays. The team compares stroke counts, ink deposit thickness, and pretreat timing against your deadline to recommend the winning approach. Clients see real cost tables instead of guesses, allowing confident sign-off before the first squeegee drops.

Blending technologies often unlocks the best pricing and looks. We screen print front logos for dense opacity, then drop custom names via large order DTF transfers that press in seconds. This hybrid path eliminates registration headaches while giving every participant a personalized garment. Operators queue films on numbered pallets, so backs pair flawlessly with pre-cured fronts. Because both machines sit steps apart, garments move through without cooling cycles that could warp alignment. The outcome is retail-level clarity delivered under demanding stadium timelines.

Batch embroidery scheduling adding premium texture to hoodies and hats

When events call for tactile luxury, our schedule engineers open dedicated blocks on thirteen-head Tajima rigs. The software clusters color-matched logos, minimizing thread changes and needle cleans across thousands of custom hoodies. That micro-level efficiency means Long Island custom shirt printing clients enjoy shorter queues and steadier costs even during peak promo seasons. Meanwhile, stitched logos resist abrasion better than ink, making them ideal for gear that tackles weather and work sites daily.

Texture lovers dig deeper by pairing chain stitch, satin columns, and 3D puff in one design. Our sampler library, powered by mass embroidery options, lets art directors feel every variant before final approval. Production managers then lock hoop sizes in advance, so garments glide from crates to arms without costly resets. By planning needle path overlaps, we prevent puckering on lightweight fleece and unstructured caps, preserving showroom aesthetics across bulk loads.

Design optimization for large batches pixel perfect at scale

Pixels leave no room for error when you promise ten thousand identical tees. That’s why pre-press artists dissect every vector according to design principles for merch that prioritize clarity under accelerated curing. They thicken fine strokes, adjust halftone angles, and verify Pantone bridges for fabric absorption differences. Those tweaks happen before screens burn, saving hours otherwise wasted on reprints. As a bonus, simplified separations drop per-unit ink costs without dulling impact.

Proofing shifts from guesswork to science once garments hit our light booths. Operators compare wet print swatches against a calibrated monitor and reference a direct to garment process overview for acceptable delta values. Any variation beyond tolerance triggers an immediate nozzle check, not an email chain. The loop ensures pixel-perfect fidelity whether we’re flashing poly performance tees or heavyweight Comfort Colors ringspun. Consistency translates into unified branding across campuses, franchises, and fanbases.

Eco friendly bulk apparel sourcing meeting green goals at volume

Sustainability pledges no longer stop at organic cotton; corporate auditors now inspect full supply chains. Our buying office curates mills that hold OEKO-TEX and WRAP certifications, then lists them inside an internal matrix clients can review. Brands eager to broadcast eco credentials often start with our guide to eco friendly bulk tees on Long Island, gaining clarity on dye methods, water recycling, and fair-labor assurances. That transparency converts ethics into measurable procurement metrics, boosting CSR reports and consumer trust alike.

Volume can still stay green without breaking budgets. Pallet purchasing through our live wholesale apparel catalog secures factory direct pricing on recycled poly blends, hemp tees, and modal fleece. Combined with energy-efficient flash units and water-based ink options, the strategy slices carbon per garment while protecting margins. Our Commack facility even recaptures exhaust heat to pre-warm dryers, shaving kilowatt hours throughout marathon shifts. Clients earn eco accolades and cost savings together.

Shipping consolidation and local pickup options streamlining delivery

Transport logistics scale quickly when five thousand custom sweatshirts must reach seventeen sales conferences simultaneously. Planners lean on route modeling software that pairs events, zip codes, and carrier hubs to protect budgets. By grouping deliveries headed to neighboring cities, we exploit zone discounts and cut cardboard waste. Organizers running pop-up merch booths appreciate insights from our article on event branding with custom tees near me, which outlines ideal in-hand dates and buffer stock counts.

Regional clients grab further savings by scheduling staggered pickups. Forklifts load color-coded pallets directly into vans, avoiding residential surcharges or weekend premiums. National campaigns tap LTL contracts that bundle shirts, custom hoodies, and promo kits on the same bill, guided by lead marketing strategies for merch campaigns that sync arrival with media launches. Whichever path you choose, dashboard tracking relays real-time scans, so stakeholders know exactly when every carton leaves Commack. That clarity turns shipping from headache into competitive advantage.

Closing Loop Metrics Marketing Synergy and Future Proof Fulfillment

Integrating custom tees inventory management with on-demand production

A flawless reorder strategy begins with accurate counts, so we sync bar-coded carton scans to a cloud dashboard the moment they leave the dryer. That live inventory management tool displays remaining stock by style, color, and size, allowing marketing teams to trigger on demand production before shelves hit danger levels. Automated low-threshold alerts prevent “out of medium” emergencies that derail pop-up shops or campus stores. At the same time, surplus detection flags slow movers for flash sales, keeping cash flow healthy and warehouse racks uncluttered. In short, data replaces guesswork while preserving the just-in-time agility e-commerce buyers expect.

On demand production only works when presses can spin up immediately, so we reserve rolling time blocks on each carousel specifically for replenishment jobs. Because screens and DTF film sets remain archived in a climate-controlled vault, operators access previous art within minutes. That readiness means a viral social post at noon can transform into 200 fresh custom tees boxed by evening. Finance departments love the approach because it converts demand spikes into revenue without tying up capital in speculative inventory. Customers, meanwhile, experience uninterrupted access to their favorite designs, reinforcing brand loyalty.

Leveraging digital proofing and Long Island web design assets for brand consistency

Brand guardians know that a misaligned logo or off-tone print can shatter credibility. To avert that risk, our digital proofing platform overlays high-resolution mockups on actual garment photos, not generic templates. Stakeholders sign off inside the portal, locking Pantone references and placement coordinates before screens burn. Every approved spec then feeds into a shared style guide that web developers, social media managers, and packaging vendors can access. Consistent visuals stretch from physical merch to online banners, ensuring audiences encounter a unified identity everywhere they look.

The same philosophy drives our collaborative relationship with regional creatives who specialize in Long Island web design synergy. Their optimized storefront layouts mirror color schemes and typography set during the apparel proofing stage. When the site refresh launches, product pages showcase real print files, guaranteeing exact fabric drape and ink saturation. Seamless hand-off between departments saves hours of back-and-forth corrections, while consumers enjoy a frictionless journey from browsing to checkout.

Cross promotion via digital business cards and merch powered Lead Marketing Strategies

Modern networking extends beyond a firm handshake; it requires tangible reminders that travel home with prospects. We package custom hoodies, caps, and tees with QR-coded swag tags that direct scanners to interactive portfolios. That landing page hosts a sleek digital business cards cross promotion experience, letting recipients instantly save contact details, project galleries, and coupon codes. By coupling wearables with mobile assets, brands bridge offline excitement and online conversion in one elegant loop.

Lead Marketing Strategies audits campaign analytics to measure scans, bounce rates, and conversions generated by each apparel drop. The feedback identifies which garment styles or colorways prompt the most digital engagement, guiding future creative decisions. Additionally, drip-email sequences reward users who upload selfies wearing the merch, transforming customers into micro-influencers. Together, these tactics stretch every promotional dollar and keep audiences interacting long after the event lights dim.

Building a wholesale custom apparel program that scales sustainably

Wholesale partners often juggle multiple launches per quarter, so price predictability ranks alongside print quality. Our tiered pricing negotiations lock bulk brackets for twelve-month periods, shielding resellers from sudden cotton market swings. Partners gain password-protected catalog views that display real-time pallet availability, exclusive colorways, and suggested retail margins. Because we aggregate orders across several accounts, mills grant deeper textile discounts that we share rather than pocket.

Sustainability remains a non-negotiable pillar of the program. We prioritize mills with water-recapture dye houses and WRAP certifications, then ship in recycled-content cartons sealed with paper tape. Carbon reporting dashboards summarize transportation emissions per thousand units, giving wholesalers proof points for eco-conscious shoppers. These environmentally responsible practices attract retailers eager to align with green values without sacrificing profitability.

Final stitch why Custom Shirt Printings Commack is the partner for bulk success

Bulk apparel success demands more than fast presses; it calls for an ecosystem where design, logistics, and marketing reinforce each other. Custom Shirt Printings supplies that ecosystem from its strategically located Commack facility, merging decades of production craft with forward-thinking technological tools. Clients receive transparency at every checkpoint, from mockup approval through shipment tracking, so surprises never sabotage deadlines.

When you need 50, 5,000, or 50,000 pieces that look and feel identical, our integrated approach proves its worth. Smart inventory dashboards slash waste, hybrid print lines preserve artistry, and cross-channel promotions prolong engagement. The result is a seamless journey that moves shirts off pallets and onto people’s backs while amplifying brand resonance. Trust the team that has perfected these systems to carry your next large-scale vision from concept to community-wide impact.

Frequently Asked Questions

Frequently Asked Questions

Question: How does Long Island custom shirt printing at your Commack facility keep large orders on schedule without sacrificing quality?

Answer: Everything happens under one roof at our Commack t-shirt fulfillment center. Designers, press operators, and the logistics crew share the same production floor, so adjustments to ink mix, screen tension, or shipping labels happen in real time rather than through slow email chains. Climate-controlled storage keeps Bella+Canvas and Comfort Colors blanks stable, while automated carousel presses hit tight registration checks every 72 impressions. The result is rapid, high-volume output that still meets retail-level standards for color accuracy and stitch density.

Question: In the blog What Are Best Bulk Strategies at Custom Shirt Printings you mention tiered pricing negotiations. How do volume t-shirt pricing tactics actually lower my per-unit cost?

Answer: We start by folding all setup fees-screen burn, digitizing, or DTF film-into the first pricing tier, so you never pay them twice as quantities climb. Once you pass each break point, our purchasing team applies pallet-level textile discounts from Gildan, Champion, and Next Level directly to your quote. We also gang screens across men’s, women’s, and youth silhouettes to cut consumable use, then share a transparent cost matrix that shows you exactly how pennies saved add up to thousands across a 5,000-piece run.

Question: Can you explain how sizing distribution forecasting and color consolidation for bulk prints help corporate logo shirt bundles avoid waste?

Answer: Our database tracks thousands of corporate orders, revealing size curves unique to industries like construction or tech conferences. We overlay that data with your attendee demographics to predict the ideal S-3XL split before production starts. At the same time, our art team audits every logo palette, merging near-identical hues so five blues become two strategic tones. Fewer surplus 3XLs and fewer ink heads mean less leftover inventory, lower freight costs, and a greener carbon footprint without dulling design vibrancy.

Question: We run a national event series and need custom hoodies and custom sweatshirts delivered to multiple venues; how do your shipping consolidation for large orders and local pickup options work?

Answer: Our t-shirt delivery logistics software groups destinations by zone, then books LTL or ground carriers to capture multi-drop discounts. Color-coded pallets leave Commack with scan-based labels that update your dashboard in real time. If one leg of the tour is within driving distance, you can choose local pickup to skip residential surcharges altogether. This blend of consolidation and will-call flexibility keeps costs low while ensuring each venue receives stock right when doors open.

Question: Our nonprofit wants eco-friendly bulk apparel sourcing plus on-demand production versus stocking inventory; can your wholesale custom apparel program handle that?

Answer: Absolutely. We curate WRAP-certified mills that offer organic cotton and recycled poly blends, then lock their pricing into a twelve-month wholesale custom apparel program so your grant budgets stay predictable. Finished cartons are scanned with barcodes into a cloud dashboard that triggers low-stock alerts. Reserve production blocks on our hybrid DTG and screen print lines let us replenish popular designs within hours, so you can operate with just-in-time agility while still touting sustainable sourcing in every campaign.

Frequently Asked Questions

Frequently Asked Questions